Ok I have quickly knocked something up.

Basically keeping cost to a minimum the jig will consist of a cheap metal wall braket as Hamish mentioned in a previous post a 3-4 mm thick aluminium base plate , chosen for ease of metal work and lightweight. This will be bolted to the bracket and a number of nylon lugs in the base plate to secure the cameras position.

The lugs will act as a kind of a tight fitting cage so the D3 can be placed snugly and have no movement. This will ensure every time the camera is taken out it is replaced in exactly the same position.

The key to this is the elimination of any moving parts. A ball joint or hinges will just cause problems

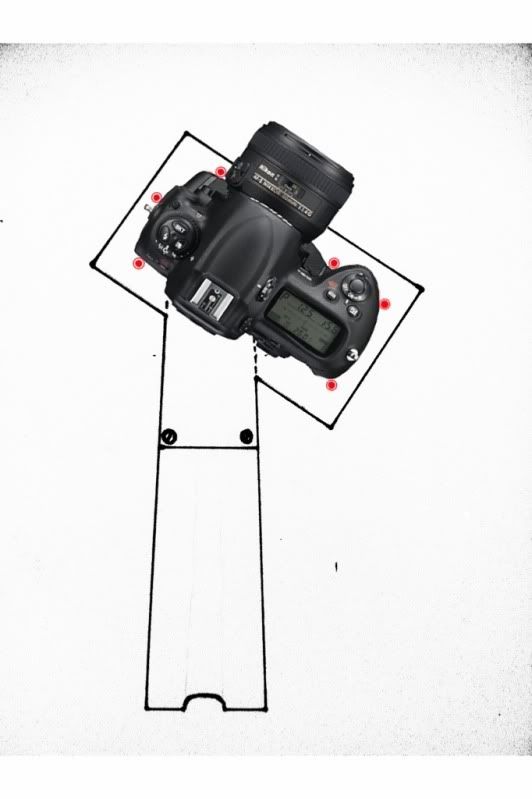

The red dots represent the nylon lugs. Commonly known as nylon standoffs mostly used for separating circuit boards in pcs. The reasons for this choice are, the nylon won't damage the camera. The standoffs can be built up in length allowing me to get around contours and obstructions on the D3

I will also add a thin rubber Mat to the aluminium plate to prevent damage and minimise vibration and shake.

For extra security I will drill a clearance hole in the alluminium in line with the tripod Mount so a bolt can secure the camera flat to the base

A side profile (not to scale)

So in my opinion this design will give.

- a sturdy platform

- exact positioning

- ease of mount and dismount

- full acsess to the cameras functions

- protection of the camera itself

To be honest the design of the bracket is not that important as long as it has a flat metal surface for bolting the business end on (the jig)

Once the bracket is in position on the wall we can set the cameras position and start building once you have decided there is no going back

Any other issues you can think of??

When do you want me round???